In the world of fabrication, manufacturing, and do-it-yourself tasks, nuts and bolts are the unsung champions that keep everything intact. No matter if you are constructing furniture, maintaining a vehicle, or embarking on a home improvement project, comprehending the different types of connectors and their functions is imperative. This expert guide will take you through An In-Depth Exploration of Nuts and Bolts, illuminating the basics and aiding you navigate the vast landscape of fasteners.

From the most common types of fasteners and their intended purposes to the details of nut types and functions, we seek to unravel the challenges of this crucial industry. You will learn to choosing the best bolts for heavy-duty construction tasks, explore how to choose the right nut and fastener for materials like wood and steel, and comprehend the role of fasteners in various applications. With a comprehensive look at substances, finishes, and custom hardware, this guide will arm you with the knowledge you require to decide wisely, be you a experienced professional or a casual enthusiast taking on your first DIY task.

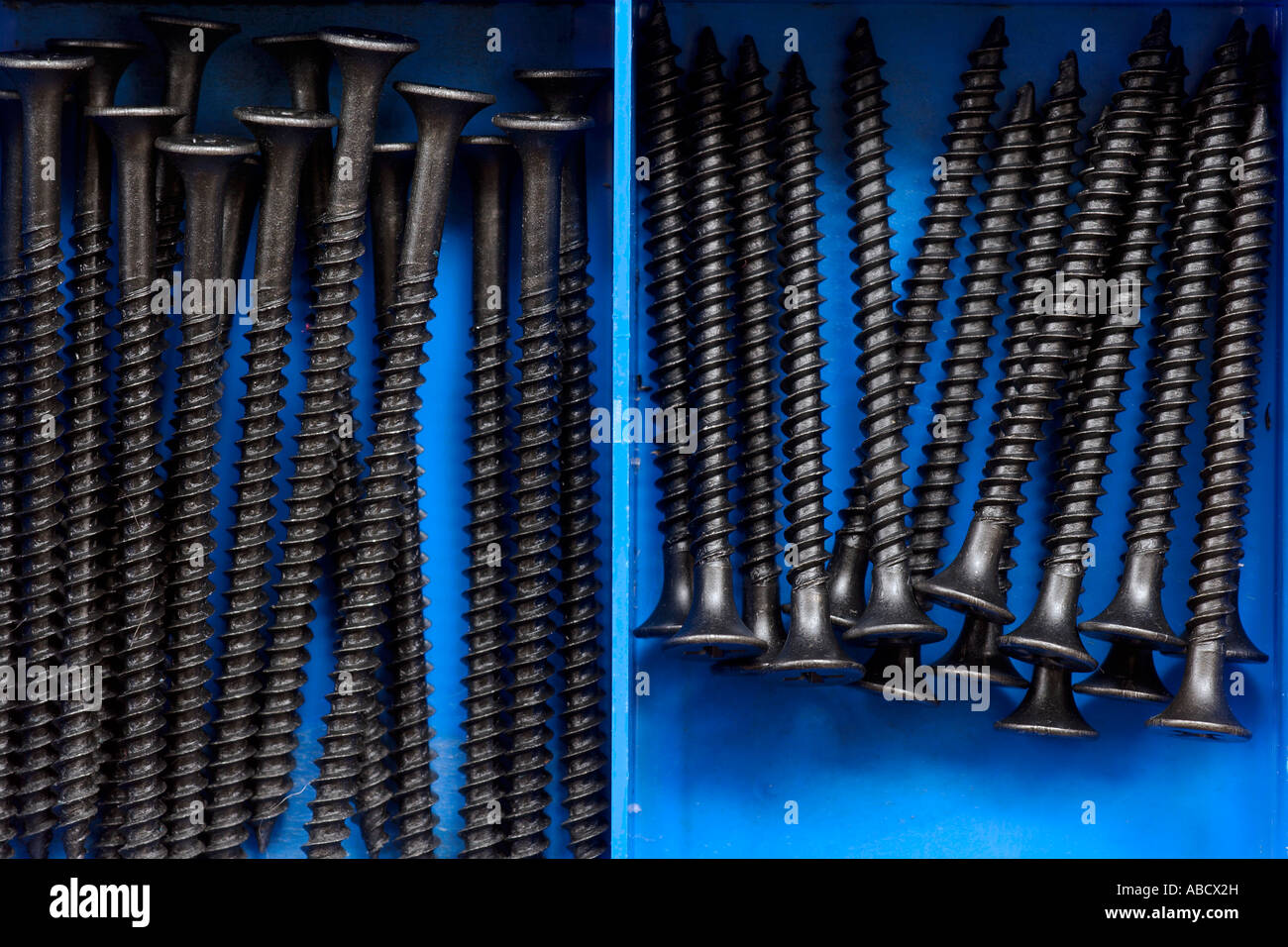

Varieties of Fasteners and Screws

Fasteners and bolts are essential elements in many industries, providing the essential attachments for countless applications. Bolts are commonly used to join components together, while fasteners serve as the complement to these bolts, ensuring a strong grip. Grasping the differences between multiple types of screws, such as hex, carriage and heavy-duty bolts, is essential for picking the suitable fastener for your specific needs. Each screw type is designed for specific applications, making it vital to choose wisely based on the project's needs.

When it comes to nuts, there is a broad array of options on offer, including regular fasteners, secured fasteners, and washer fasteners. Common fasteners are often used in many applications, while lock fasteners provide better security by preventing loosening due to vibrations. Washer nuts include a integrated base-like base, which balances the load consistently and helps reduce the risk of damage to the materials being fastened. Knowing these distinctions will help you choose which nut best fits your chosen fastener type.

In addition to the regular kinds, unique bolts are offered for specific applications. These include security bolts that are tamper-proof and nylon lock fasteners that incorporate synthetic inserts to provide additional protection against detachment. Furthermore, support screws are vital for holding structures to concrete, while expandable bolts offer superior holding power in different materials. By getting to know you can try here with these types of nuts and screws, you can ensure that your fastener choices are both effective and reliable.

Substances and Finishes

When it comes to nuts and bolts, the choice of material significantly impacts their performance and durability. Steel is one of the most commonly used materials due to its toughness and affordability. In the iron category, there are various types and compositions, including carbon alloy and composite steel, each suitable for different applications. For projects requiring lightweight yet strong fasteners, titanium is an excellent choice, providing resistance to corrosion and high temperatures. On special info , brass provides superb corrosion protection and is commonly utilized in electrical applications.

Finishes play a crucial role in enhancing the lifespan of fasteners and screws, particularly in conditions prone to humidity or corrosive substances. Zinc plating is one of the most prevalent coatings, providing a protective barrier against rust and degradation. It's important to differentiate between zinc-plated and hot-dipped fasteners, as galvanized bolts undergo a more robust coating process, enhancing their resistance to the environment significantly. Understanding Full Article is essential for choosing components that will maintain their quality over time.

In conjunction to defensive coatings, the surface treatment of fasteners and screws can affect their friction characteristics and overall functionality. Specialty finishes, like those found on corrosion-resistant fasteners and bolts, can further enhance functionality in specific settings, such as construction projects in the outdoors or marine conditions. When selecting fasteners for particular tasks, taking into account both the substance and finish can lead to optimal longevity and trustworthiness in the use.

Consumer Guides and Contrasts

In the process of choosing fasteners, comprehending the distinctions between metric and standard systems is essential. Metric fasteners are gauged in mm and are commonly used in European Union and Asian products, whereas imperial fasteners use in and are prevalent in North America. This separation can affect your project significantly, notably if you must replace or align with current fasteners. Take the time to determine which system is appropriate for your needs and verify that you have the right tools to gauge both types properly.

Accurately measuring nuts and bolts precisely is key to a productive installation. The major measurements to consider include diameter, length, and threads per inch. For bolts, you will must measure the shaft diameter and the measurement from the base of the head to the point of the bolt. For nuts, confirm that the internal size fits the bolt's shank size for a tight fit. With proper measuring techniques, you can avoid compatibility issues that may cause project delays or failures.

Quality fasteners can be crucial the longevity and reliability of your projects. Search for trustworthy brands that provide concise specifications regarding their products' grades and material makeups. A bolt strength analytical chart can help you comprehend which types of bolts are most appropriate for heavy-duty applications versus basic tasks. Additionally, familiarize yourself with the terminology in a nuts and bolts lexicon to make sure you pick the correct fasteners for your specific needs, whether for building, automotive repairs, or home improvement projects.